There are gallons of water stored in the tank of a water softener system at any given time. When the tank has more water than it can hold, then you are faced with the problem of overflowing.

Why is my water softener overflowing? In a nutshell, water softener overflowing occurs when excess water is stored in the water softener tank due to blockage in water flow from the tank to the house.

There is a brine line on the tank that indicates the maximum amount of water that should be in the tank for it to function properly. Exceeding this line will cause the water to overflow.

There are several ways to troubleshoot this problem, which we’ll discuss in this article:

- Check the control valve

- Faulty regeneration process

- Inspect the brine line

- Check for salt clog

- Check drain line

- Blocked injector

- Seal or Piston malfunction

Check Faulty Control Valve

Control valve is the unit in charge of controlling the amount of hard water that goes in and out of the tank. The brine tank has a process of regenerating the resin and a process where it cleans itself of the contaminants and minerals.

If this cycle is disrupted or doesn’t unfold as it should, then you will face a malfunction that will likely lead to overflowing at some point. At first, you just might notice that the system isn’t as efficient. However, if not addressed overtime, it will lead to overflowing.

This is why the control valve should be regularly maintained and in perfect working condition at all times.

Every now and again, adjust the valve in order to see if the new settings will align with the water that you are getting on the other end. Think of it as a routine check to make sure the valve is in order.

Check Faulty Regeneration Process

The process of regeneration is in place to rid the water of the calcium and magnesium minerals. It accomplishes this by mixing the minerals with the resin bed.

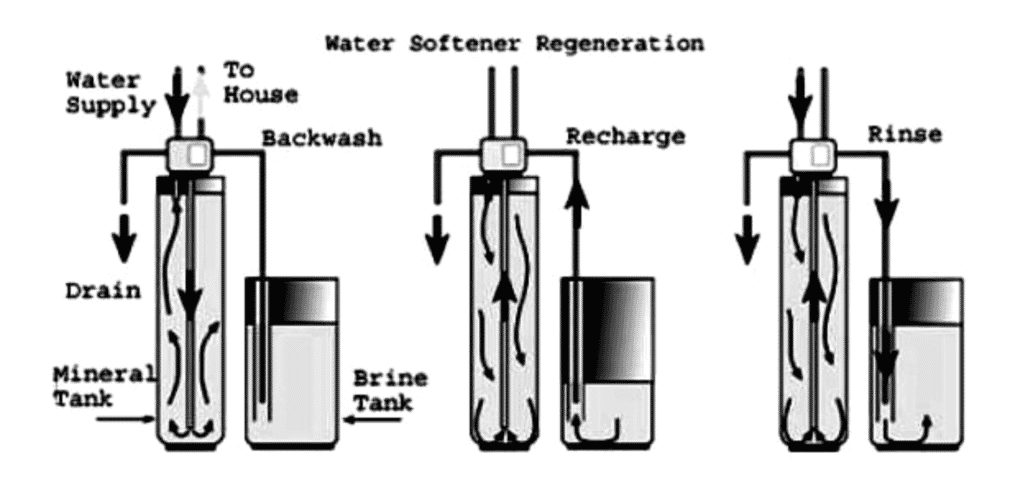

The first thing that happens is a backwash cycle. During this process, the control valve should reverse the flow of the water and flush the tank.

Once that is done, a brine solution is inserted into the mineral tank, where the process of ionization takes place.

During the ionization process, the sodium ions bind together. The positively charged minerals from the magnesium and calcium react with the negatively charged resin ions and are flushed out of the tank.

The final stage takes place when the tank is rinsed so that the process can commence once more. When the resin beds become saturated from the magnesium and calcium, the control valve steps in again and starts a brand new regeneration cycle.

This process can go wrong at a couple of different stages.

Inspect the Brine Line Before & After Regeneration

If everything works as it should, then the regeneration cycle should ideally fill the brine tank anywhere from a quarter to halfway full.

If the water that is supposed to be drawn from the brine isn’t drawn out completely during the next filling, you will have more water than you should. Over time, this will lead to overflowing. In short, the water levels should stay the same and not increase during every backwash cycle.

If your water softener is overflowing, you want to have a gradual approach. This means that you check on the fundamentals first. Is the tube attached to the brine well? There should be a tube that connects the tank to the control valve. Find it and make sure that everything is okay with it.

Once you’ve established that, it’s time to move on to removing the lid off the brine tank and checking if the brine is fitted to the safety float. If you experience water and air leaks, that is a reason for concern, and it’s probably why you are having overflowing problems.

If these two are in order and in place, then you want to check if your tank is overflowing as a result of obstructions.

Check For Salt Clog

The most common obstruction that disrupts the water flow and draining is a salt clog. Salt clogs prevent the water from going into the brine tank. You will have to find the salt clog and either poke it open or use a solution that will get rid of it.

This can be somewhat of a difficult task because salt clogs grow to be super hard. If you can reach the clog, it’s always better to attempt to manually break it down by taking a stick and attempting to dislodge the clog. If this doesn’t work, then you can reach for a solution that will dissolve the salt crust.

The next thing that you should be looking for is the drain line. Is it clogged or swirled at an angle that could restrict the water flow?

Check the Drain Line

If the drain line is clogged, it will put a considerable amount of stress on the control valve. When the float control gets salt-clogged, simply take it off and give it a nice thorough washing. You’ll be able to see on the spot if there is something inside obstructing the water flow.

If there are high iron levels that are passing through your water installation on a day-to-day basis, your pipes will rust and collect hard minerals from the water passing through.

That’s why it’s a good idea to clean the drain line on a regular basis. By doing this, you are making sure that the brine line is working optimally.

The clog can also take place when the brine line comes in contact with the water softener valve. It’s not unusual for different types of debris to enter the tank and get pulled through the valve.

If this is a regular occurrence, at some point, the valve will become unable to draw from the brine tank. Once again, a complete wash-down and cleaning should clear the tube of the debris that is blocking the flow and solve your overflowing problem.

Inspect the Float Cap

Make sure the float cap that controls the brine levels is in place as it should be. Float caps are known to lose their grip over time and become liabilities.

This affects the vibration of the softener system and puts more stress on the safety valve. As a result, water keeps on being added to the tank on a continuous basis, leading to overflowing.

Take a Look at the Injector

Another common cause of overflowing is an obstruction at the injector. The injector has a tiny hole in order to create suction and draw from the brine. If the hole is blocked or clogged, you will most definitely experience overflowing.

The fix is once again the same: inspect the injector and do your best to thoroughly clean it from external dirt or salt.

Don’t worry if you cannot unclog the injector. The part itself is widely available and inexpensive, so you can just replace it and be done with it.

Seal or Pistons Malfunction

If everything is in order with the brine tank and lines, then the overflowing problem might lie with the seals, spacers, or pistons.

If the softener has trouble drawing brine during its regeneration cycle, you might be looking at a torn seal. If this happens to be the case, you will need to remove the drain line along with the brine line and take a look to check if there is water flowing through the valve.

If it is, then the softening system will probably require a replacement of the seals or piston. Now, if this is the problem that you’re facing, you are better off hiring a professional to do the job.

Proceed With Care

When looking at the potential causes for the overflowing, always be aware of how you are disassembling and assembling the parts of the water softener. You might cause more damage than good if you are using excessive force or treat the parts with reckless abandon.

Make sure that each of the moving arts is placed back in its correct position. Wash and inspect the parts in the order that you remove them, and once you’re done, reattach them in the reverse order.

Conclusion

Water overflowing from a water softener might seem like a disaster when it occurs, but for the most part, you will be able to fix the problem by carefully removing the clogged or problematic part and giving it a good cleaning.

The name of the game here is not expertise but rather patience and understanding how to troubleshoot. Once you become familiar with the parts of the softener, you will grow out of depending on service calls for small things and take these matters into your own hands.

Remember, nine times out of ten, overflowing is the result of poor maintenance or complete lack of it.