Traditional salt-based water softeners mostly consist of two tanks: a resin tank and a brine tank.

The resin tank is the primary tank where the ion exchange process takes place. However, this doesn’t mean that the brine tank is any less important, as the brine solution made in the brine tank is responsible for keeping the resin charged.

In this article, we will cover all you need to know about the water softener brine tank, how much water should be in it, and how to maintain & troubleshoot common brine tank issues.

What is a Water Softener Brine Tank?

Brine tank is the component of a water softener that keeps the system running by cleaning and regenerating the resin.

As we established in the introduction, water softeners have a resin tank and a brine tank. The former tank removes hard water minerals like calcium or magnesium as their positively charged molecules are attracted and trapped by the resin and replaced with negatively charged sodium ions. This process is called ion exchange.

However, every resin has its own softening capacity and limits on the number of molecules it can trap before these molecules are flushed out by a regen cycle. This capacity is known as the grain capacity. Before the mineral molecules trapped in the resin get saturated, the resin should be cleaned, and it needs to regain its negative charge status to continue operating efficiently.

That’s when the brine tank comes into the picture. The brine tank is where the softener salt goes, and the sodium salt has two key duties: cleaning the resin from trapped minerals and recharging it since sodium naturally has a negative charge.

To that end, water softeners are often pre-programmed to run a regeneration cycle once every week. During this cycle, a brine solution prepared with softener salt and water inside the brine tank travels through the whole system, collects mineral buildup from within the system, and flushes itself out alongside minerals down the drain line.

How Does a Water Softener Brine Tank Work?

A water softener brine tank typically needs salt every month. Of course, the tank also needs a certain amount of water to make a brine solution, but whether you add water or not depends on the tank type you have.

Old water softeners usually come with a wet brine tank. For a wet brine tank, you might need to add new water between two regeneration cycles, as these softening systems don’t use automated brine-making technology. When checking water levels inside the tank or pouring in new water, you should always follow the instruction manual of the unit.

However, most new softening devices utilize a dry brine tank and have their own computers. With this type of system, you don’t need to add any water to the tank.

The computers of these units automatically measure how much brine is needed to clean the system and recharge the resin. So, when the regen time comes, they’ll automatically fill the tank with just enough water to prepare a solution without you needing to do anything.

The amount of salt you need to add will differ depending on the size of the tank, the grain capacity of the softening resin, the hardness of the water, and manufacturer instructions. That’s also the case for adding water to wet brine tanks.

What is the Adequate Water Softener Brine Tank Salt Level?

Your brine tank should be at least a quarter full of salt, which comes at around four to six inches below the top of the tank. This makes for excellent efficiency and keeps the salt level over the water line.

This rule is particularly important if you have a dry brine tank. Since such systems have an automated process for preparing brine, adding more or less salt than required might lead to inefficient regeneration.

For instance, if you add too much salt, the water might leave a certain amount of salt in a semi-dissolved state due to the improper ratio. Once the water withdraws from the brine tank, semi-dissolved salt will strongly clump together, forming a salt bridge, which is a phenomenon you should do your best to avoid.

Putting less salt than the system requires, on the other hand, means that the brine solution will not be as strong as it should be in ideal conditions, so it won’t be able to thoroughly clean or recharge the resin.

How Much Water Should Be in the Brine Tank After Regeneration?

The amount of water a tank needs to have after a regeneration cycle is only applicable to wet brine tanks. Depending on the instructions of the manufacturer, maintaining 3 to 6 gallons (6 to 10 inches) of water inside the tank is ideal.

Dry tanks, on the other hand, have a computerized process for preparing brine, as we established before. That means you will only have water in your tank for an hour or two before the softener goes through the regeneration cycle.

However, there should be no water inside the brine tank otherwise, neither between the regeneration cycles nor after regeneration. If there’s water inside the tank, you’re probably face to face with another dreaded water softener phenomenon called standing water.

The reasons behind standing water inside the brine talk might vary from salt-related issues like salt bridges to clogged lines due to mineral or salt buildup.

Water Softener Brine Tank Maintenance

This section will answer some commonly asked questions about brine tank maintenance.

It ultimately depends on the recommendation of the manufacturer of your softening unit, but the general recommendation is that a brine tank should be at least one-quarter full of salt.

More salt than required may lead to problems like salt bridges. Less salt than necessary, on the other hand, will result in an ineffective brine solution, and consequently, an ineffective resin bed that won’t be able to soften your water as much as desired.

If your softener has the ideal grain capacity for your house and is programmed properly, you will most likely use around 40 to 50 pounds of salt a month.

You should add salt to your softener every 4 – 6 weeks. This number might vary depending on:

– The water hardness: As the water hardness increases, the resin will trap more mineral molecules and become ineffective very quickly. This means that the regeneration frequency will also increase and the device will start using more salt.

– Water use at your household: During times when your water use hits a peak, the softening device will inevitably work overtime, leading to more frequent regen cycles. Summer weeks in which every member of the household typically has one or two showers per day might be a good example to that.

– The type of salt: If you don’t use the water softener salt recommended by the manufacturer of your device, it’s likely that the amount of salt the device utilizes will vary depending on the compatibility of the device with that salt. Also, not all softener salt has the same levels of solubility, so, depending on your purchase, the frequency of you adding salt to the system might need to change.

Manufacturers mostly recommend that customers clean their water softening devices once every year, but it depends on how hard or iron-rich the water supply is. If you’re also suffering from iron problems, it’s best to clean the brine tank thoroughly every time you add salt.

But, this is not a big deal, since the whole process should only take half an hour with the right guidance.

A brine tank can get clogged due to salt crusts blocking the water lines. Low quality salt or putting too much salt into the tank might lead to this particular problem.

To unclog it, you should:

1. Turn off the water softening unit.

2. Remove the lines coming in and going out of the brine tank.

3. Wash the inside of the lines with pressurized water until there’s no salt left.

4. Take the salt out of the tank.

5. Remove all the water from the bottom of the brine tank.

6. Pour hot water over the remaining salt.

7. Clear away the salt stuck to the tank’s surface carefully with a sharp object.

8. Rinse the inside of the tank thoroughly.

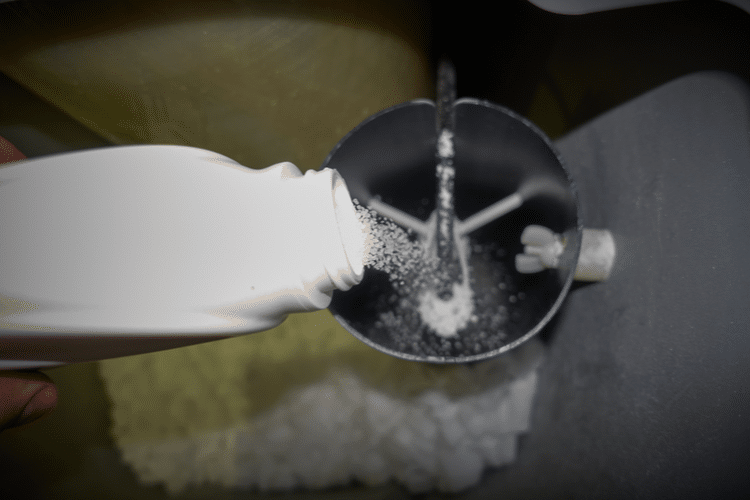

9. Add new salt to the brine tank.

10. Run a manual regen cycle by consulting the instruction manual of the device.

If the system doesn’t return to normal after these ten steps, contact the customer service of the manufacturer.

Yes, you can replace a damaged brine tank, but before doing so, it’s still best to consult the manufacturer of the water softener system. Not every manufacturer sells these tanks separately, and a random tank you’ll purchase might not be compatible with your softening unit.

Repairing and replacing a brine tank can cost anywhere between $125 to $700, depending on the manufacturer and whether you need a plumber/technician to carry out the replacement.

When the expenses go north of that range, it might be better to invest in a new and good water softening unit as the cost of a new device won’t be more than the cost of repair.

Conclusion

Traditional water softeners operate based on ion exchange in which a negatively charged resin attracts, traps, and replaces mineral molecules with those of sodium. A brine solution prepared in the brine tanks of these devices is responsible for keeping the resin clean and recharging it.

Since a continuously cleaned and recharged resin is paramount for softening devices to operate effectively, the brine tank is as crucial a component as the resin tank, and you should do your best to maintain it.

To that end, use high-quality salt, adding only as much as the manufacturer recommends, and clean the tank whenever you add new salt.

I keep my salt level just below the normal water level in the brine tank. You want to be able to open the brine tank and quickly determine if there are any obvious problems. You need to have water in the tank to make brine, and too much water may indicate that your previous regeneration was not successful. I also marked the normal tank level on the outside of the brine tank. So, opening the tank you should be able to determine that there is salt in the tank, there is water and confirm that the water level is normal.