Ion exchange is a chemical process that occurs from exchanging unwanted ions with ions of an equivalent charge by passing them through a resin.

This process is commonly used in water softening. It’s also a common practice in the food processing industry.

Ion Exchange Method For Water Softening

The ion exchange method of exchanging two sets of ions with the same charge can be used to remove and soften the dissolved minerals in hard water to more acceptable levels.

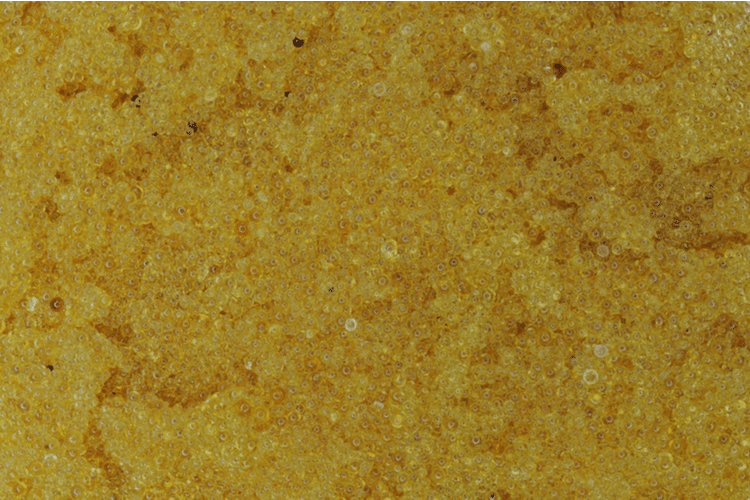

This method uses a resin bed equipped with either anion, cation, or specialty loaded layers. It may have just one layer or a combination of two layers.

Not all water treatments require ion exchange, but water softening is the most common circumstance for its use.

Water becomes hard when high levels of dissolved minerals such as calcium and magnesium are present in the water. These minerals can accumulate in pipes and fixtures of the home, causing damage and leaving unpleasant stains.

However, homeowners can remove the issue by replacing the ions with sodium and potassium, which hold an equivalent charge. The water is then flushed, and excess ions are pushed out in a regeneration process that resets the resin and removes excess ions.

Contaminants Removed By Ion Exchange

When used appropriately, an ion exchange method can remove a variety of contaminants such as dissolved minerals and radioactive particles.

A mixed medium resin with two layers (one anion layer and one cation layer) can remove a variety of contaminants including, but not limited to:

- Uranium

- Nitrate

- Arsenic

- Radium

- Magnesium

- Iron

- Calcium

- Manganese

- Boron

- Mercury, lead, and other heavy metals like nickel

- Chromate

- Perchlorate

The quality of the ion exchanger and impurities in the water will affect what can be removed with this method. High concentrations of chlorine can interfere with some iron exchange methods.

When treating hard water, the type of resin used will determine what contaminants the system removes from the water and how the resin will react in different environments. After all, homeowners and businesses can use ion exchange for more than just water softening.

The anion and cationic resins in an ion exchange system can accomplish:

- Disinfection

- Deionization

- Dealkalization

- Denitrification

Anion resins use a weak or strong acidic solution making them a prime candidate for removing calcium and magnesium, two of the culprits for hard water. Ion exchange can also change the pH of the water by removing high alkalinity without needing to add additional acids.

Cationic resins use a weak or strong base solution, making them a good solution for acidic water and the removal of silica.

Specialty resins vary, but they are usually more specialized and more expensive. They are capable of working in very dilute environments and can employ features like magnetic ions for use with heavy metals and microscopic particulate.

Contaminants Not Removed By Ion Exchange

Bacteria, viruses, and pieces of organic matter are too big and not negatively charged, so they cannot be removed by ion exchange. Pollutants like fluoride, arsenic, and lithium can be very difficult for an ion exchange system to remove.

While ion exchanges are highly efficient and work well for water softening and the removal of contaminates, they can’t remove everything.

Some contaminants are too large for displacement by equivalent ions, or they react negatively to the presence of an acid or base solution.

- Because of this, ion exchange systems usually work alongside other filtration systems.

- The installation of an ion exchange system is rarely the first layer.

- Usually, companies will install it as the third or fourth step for treating water.

Filtration systems that use carbon and fine screens can remove other contaminants before the water moves to ion exchange, decreasing the chances of damage to the resin by large particulates or adverse reactions and increasing the longevity of the resin.

Water with high amounts of lead can also pose a unique problem.

Although ion exchange can remove iron from water in small amounts, it must be present in the form of a ferrous ion which is iron that hasn’t been in contact with air and oxygen and hasn’t oxidized.

If the iron reacts with air and oxygen and then dissolves in water before it reaches the ion exchange, it will change to a form that the softener can’t extract. It can then build up and clog the resin.

This is called iron fouling, and it can damage a resin and create additional problems like plugging the water softening component.

Ion Exchange in Food Processing

The ion exchange method has many different uses outside of water treatment in the food industry. It assists with the purification of juice, decolorizing sugar, and even extracting Xylitol, used as a popular food sweetener from plants.

Traditionally, ion exchange is used for wastewater treatment. This ensures the water leaving food processing plants is clean enough to be used in food production and safe enough to rejoin the environment when it’s disposed of.

However, many other products are made possible because of ion exchange. Due to its ability to work on such a small level, ion exchange allows food processors to go one step further in the purification and deashing of white or clear products like sugar, beer, and olive oil.

A solution is added to the beer “broth” while fermenting. It attracts impurities, allowing the brewer to remove them more efficiently and with a higher degree of confidence.

White sugar, which often comes from beet or cane juice, is decolorized using ion exchange to separate the colors of the material before distilling. This leaves an end product that’s pure white without any ashing or dilute colors of the original juice.

The dairy and fitness industries benefit from ion exchange’s ability to isolate and extract whey protein from milk. A process previously done through numerous distillation techniques is now made more accessible and more efficient through the correct combination of cations and anions that can attract and isolate whey protein ions.