Water softeners are incredibly useful and make certain aspects of life easier, which is why everyone loves them. Of course, this is only until you need to clean them.

The issue that a lot of people have when cleaning water softeners is that they’re large appliances that most of us are not very familiar with.

Luckily, you don’t need to be a self-taught mechanic to maintain these devices.

Here are just a few tips that can help you get the hang of water softener maintenance in no time at all:

- Get the right salt;

- Make sure the resin tank has salt

- Get rid of salt bridges

- Get rid of salt mush

- Clean out the brine tank

- Clean out the resin tank

- Set the right regeneration frequency

- Clean the valves and the hoses

- Be quick at tackling issues

Why Maintain Your Water Softener?

The reason why you need to maintain your softener is the same as for any other appliance that you own. Regular maintenance ensures that everything is running as it should, and it can also extend the appliance’s lifetime.

Water softeners can easily develop issues if you don’t check up on them for long periods of time. Leaking hoses, blocked input valves, and damaged pumps are just some of the most common issues that can happen. These can also lead to larger issues and even irreparable damage to your unit after some time.

Faults in the system can also impact the overall condition of your device. The more strain the components are under, the more frequently they’ll break and need to be fixed or replaced.

Maintaining your water softener is the best way to ensure you can keep using it for years.

How Often Should You Maintain a Water Softener?

Most of the maintenance tips in our article are going to rKind Water Systemslve around the brine tank. The main reason for this is that the resin tank can’t be opened, so the only maintenance that you need to do on it involves the valves.

You’ll want to check on the state of the brine tank and the salt inside at least once a week. We’ll tell you what to look for, and if you see a need for it, you can do the maintenance as often as you like.

As for the valves, hard water is notorious for causing limescale. While the water leaving the softener is fine, the water that passes through the components leading to the resin tank gets a large dose of calcium and magnesium every day, which is why the valves leading into the tank will need more frequent maintenance.

You’ll want to check the valves leading from the tank to the house every once in a while, but the components that lead to the resin tank should be checked around once a month or so.

Maintenance Tips

We’ve compiled a list of what we think are the most important maintenance procedures you need to do to make sure your softener runs well for a very long time. We’ve also divided them into several different sections so that you can keep track of which tips are for which part of the device easily.

Get the Right Salt

This is a pretty straightforward one – ensure you get the right salt for your water softener.

Most water softener manufacturers will tell you exactly what sort of salt you should be using with their devices. There are many different types of water softener salt, but they’re generally all acceptable.

Rock salt is the cheapest option you can go for, but the high amounts of calcium sulfate make it less soluble than other salts, which causes a lot of sodium buildup in the valves.

Solar salt or evaporated salt are pricier, but they’re a better choice for anyone that doesn’t want to have to clean their water softener valves every week because they got blocked.

Fine grain and pure white are the only two characteristics that you should really be looking for. Look for something as pure as possible without any additional chemicals or coloring, and make sure that it’s in crystals rather than pellets. This is so that the salt gets dissolved more easily and actually passes through the system rather than blocking it.

Aside from that, the brand doesn’t really matter, so pick whichever one you think is best and most convenient for you.

Make Sure the Resin Tank Has Salt

The resin tank is going to need to be filled with salt regularly. The amount of salt that your water softener uses is going to depend on how frequently the regeneration cycle runs.

Every system is different, and some regeneration cycles use more salt than others, so the best way to gauge how much salt you need to add is through a visual inspection.

Open up the brine tank and make sure that the salt level is up to at least the ⅓ mark of the tank. If this seems low to you, then you can fill up your brine tank up to the halfway point if you want; however, we don’t recommend exceeding that limit.

Additionally, you should consult your manual since it’s more than likely going to have information on the recommended amount of salt that you should have in your brine tank. Just keep in mind that putting in too much salt causes salt bridges to form due to the salt not getting used up on time.

Get Rid of Salt Bridges

Speaking of, a salt bridge is essentially a crust layer that forms in the brine tank. Salt that stays at the top of the tank will constantly get soaked and then dried out as the water levels rise and fall. This will cause it to eventually congeal and start fusing together.

This causes the salt to turn too hard to dissolve properly, and the system essentially thinks that there’s no salt it can use for the regeneration cycle. Luckily, the solution is incredibly simple.

Take a hammer or any hard object that you have nearby and break up the salt bridge. You don’t need to break all of the salt bridge into smaller pieces, but you want to have a decent amount of fine salt at the bottom that can dissolve easily so the system can use it.

Get Rid of Salt Mush

Salt mush happens when salt stays at the bottom of the brine tank soaked in water but doesn’t get used by the system. While it’s not as hard as a salt bridge, the large lumps of mushy salt are still stuck together and can clog your system if they’re not broken apart.

Similarly to the salt bridge, all you need is something long and hard that can reach the brine tank bottom, like a broom handle. Once you have something, just stick it into the brine tank and stir the mush around until you can’t feel as much resistance at the bottom.

Both the salt bridge and salt mush will come back, but giving the brine tank a good stir once a week should be enough to manage them.

Additionally, brine tanks aren’t so fragile that they can be damaged by a broom handle, but some models are made out of plastic, so you might want to be careful with how much force you use.

Cleaning Out the Brine Tank

The first thing you need to do is turn off the water in the tank. Next, detach the hose connecting the two tanks. After that’s done, you can start taking the salt out of the tank. You can throw it out, but you can also just put it in a bucket to the side.

After the salt is gone, remove both the float assembly and the grid plate it’s attached to at the bottom. When the tank is empty, tip it over gently and drain any water inside. Make sure that you pour it down the drain rather than in your garden since salt water will kill any plants that you have.

The components

While the float assembly is out of the tank, we’d recommend filling a bucket up with warm water and sticking it inside for half an hour or so. This will help loosen any salt that might have stuck to it, but if you still see some clinging to the assembly, all you need to do is get a brush and gently scrub it off.

The tank itself only needs a sponge, some dish soap, and a bit of elbow grease. You can also use a solution of one part of vinegar to 2 parts of water to spray the tank on the inside and scrub out any stains on the walls.

Once the tank has been scrubbed, tip it on its side again and use a hose to rinse out the inside. Keep it like that until it’s decently dry. In the meantime, while you wait for the tank to dry, you can clean the grid that the float assembly attaches to.

The float assembly goes into a plastic cylinder that’s either part of the grid or can be attached and detached from it. Pour a bit of warm water into the cylinder or stick it in a bucket to help loosen any salt stuck to the walls, and use a brush to clean out the inside. Use the same method to clean out the grid.

Put everything back together

Once the tank is relatively dry, stand it back up again and use a cloth to gather up any leftover water. Put the grid back into place, attach the cylinder and the float assembly, and fill the tank with salt again.

Once all of that is done, attach the brine tank to the resin tank once again and proceed as you normally would.

Cleaning Out the Resin Tank

The resin tank can also be cleaned, though the process is a lot more complicated than with the brine tank. You need to open up the resin tank, pour out the resin into a bucket or some sort of container, and use a resin cleaner.

Here’s the thing, though, resin doesn’t really need to be cleaned. The point of the regeneration cycle is to keep the resin charged up and capable of ion exchange. The resin beads will eventually lose their potency, but even systems with incredibly high flow rates only need their resin to be replaced once every 10 years or so.

Additionally, opening up the resin tank is a massive undertaking, and if you’re not careful, you can even manage to void your warranty by doing it. In fact, certain agreements explicitly state that the resin tank can only be opened by professionals that have been approved by the product’s manufacturers.

The bottom line is this. If the water isn’t getting softened and you feel like the culprit is the resin itself, then the best thing to do is call a professional to check your system out for you. They’ll know exactly what to do and how to handle the resin problem if one exists.

Regeneration Frequency

Some people suggest putting the regeneration timer to run every day, while others say that twice a week is the perfect interval. The truth is that it’ll all depend on the size of your home and your flow rate.

Larger homes that use more water will need the regeneration to run more frequently to properly recharge the resin in between cycles. As for when you should set it, that’s up to you.

It’s very easy to tell when the water isn’t getting softened since the taste will be different, and if you pour it into a glass, the glass will have very noticeable water stains due to the mineral concentration.

The water not getting softened means that the resin doesn’t have enough sodium to do its thing. This means that you should set your regen cycle to run more frequently.

We’d suggest trying out different settings. If setting the cycle to three days doesn’t regenerate the resin, set it to run on two. If that isn’t enough either, set it to run every day.

Keeping your resin regenerated ensures that you can use it for a long time, so make sure that your cycle is set properly.

Valves and Hoses

Valves and hoses need to be detached from the system before they can be checked and cleaned. The first step is obviously going to be to stop the system and make sure there’s no water or brine in the hoses.

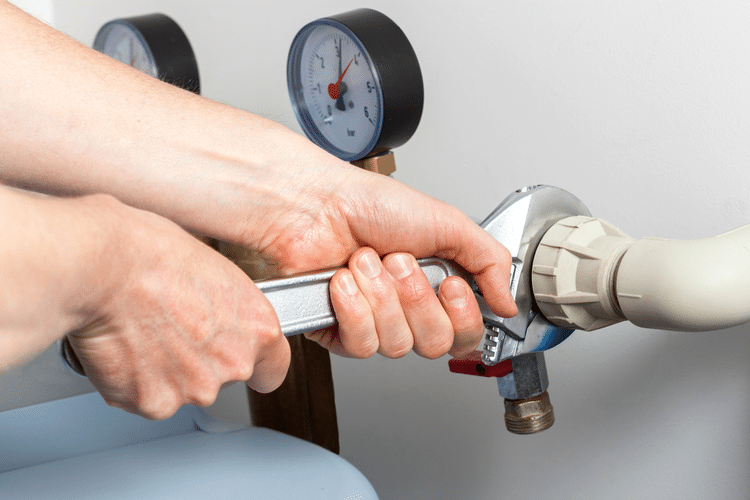

Once the system is off, detach the valves from both the brine tank and the resin tank ends, and slide the hose off. Do this for the resin tank drain line and the water input and output line.

Once all of the valves are detached, go ahead and put them in a bucket of warm water to soak. While they’re soaking, take the hoses and run some warm water through them to get rid of any salt buildup.

After 10-15 minutes, remove the valves, get a small brush, and start scrubbing around the edges. You’re looking for and trying to remove limescale and sodium deposits. The water should have loosened things up, so you won’t need to scrub too hard to clean the valves. Just don’t forget to scrub the insides of the valves as well.

Once they’ve been scrubbed, rinse them out, put them to the side so they can dry a bit, and put everything back together again.

Be Quick

Once you notice an issue or even a potential issue with your system, you’ll want to move fast and fix it as soon as possible. You can try to handle things on your own if you feel capable, or you can call a professional.

Regardless of which route you decide to go down, taking care of small issues before they turn into major ones is a good way to ensure that your softener stays functional for years.

Conclusion

The main thing that you need to keep an eye on is the brine tank. Break up any salt bridges or salt mush that has formed to ensure that the salt dissolves properly, and make sure you clean it out every month or so.

The valves and the hoses should also be rinsed out with warm water to ensure that there aren’t any sodium deposits stuck inside.

And finally, see to it that the resin always has enough sodium to soften the water so that the regen process can run properly.

It’s good to know that you should check on your water softener every now and then to extend its life. My husband and I decided that it would be a good idea to get one installed for our home within the next couple of weeks, so I wanted to know some tips on properly taking care of one so it can last a long time. We’ll keep these tips in mind once we get a water softener installed.